The New Era of 3D-Printing Technology in Automotive Industry

- Published | 12 September 2018

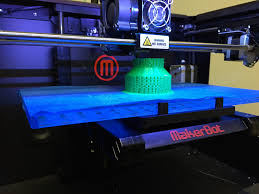

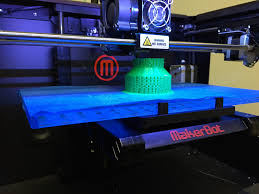

United States: The recent phenomena of additive manufacturing, in order to come up with the new designs, efficient cost reducing methods and reduced lead time in the manufacturing of auto vehicles, is witnessing the innovative use of 3D-Printing within the automotive industry. Industrial 3D printing becomes advantageous when it comes to producing rare or complex parts that conventional manufacturing process could only produce at high costs even for low volumes. In addition to this, this technology affords increased design freedom if a component is to handle multiple functions, such as current or cooling. General Motors is increasing the usage of 3-D printing at its plants to streamline its operation, which carries the potential to cut on the millions of dollars in its annual production cost.

According to the higher management of General Motors, the company realise the increased utilisation of technology in every walk of life which makes the processes faster and less rigorous. Thus, they are also utilising the technological advancements to extend and better standardize their operations. The technology of 3-D printing is being adopted by various industries across the U.S. to manufacture rapid prototype parts for manufacturing and design. General Motor is thus adopting this technology to quickly build accessories and tools for the workers at the plant. As per Zane Meike, the lead at the facility of additive manufacturing at General Motors, an approximately 35,000 3-D printing machine, involving housing, at General Motor's Lansing Delta Township plant has saved the company more than USD 300,000 over two years on tools and other accessories. The Lansing Delta Township plant of the company, that manufactures the Buick Enclave and Chevrolet Traverse, originally purchased the 3-D Printing machine to make kitting boxes for parts. However, other usages which were gradually suggested and submitted by plant workers, continue to be adopted in order to improve the safety measures and for savings on the cost on production. In the light of the advantages of 3-D Printing, General Motors is working to standardize 3-D printing and create the best practices within all the plants of the company across the globe.

According to BlueWeave Consulting, the highly competitive automobile industry, in order to satisfy the consumer wants, is working towards all the best class methodologies that help them to integrate new technology with the existing one that include implementation of systems and processes that can further assist human workers. The modern buyer of auto vehicles looks for variety and quality in order to make the purchasing decision and since this product category involves high level of involvement, the buyers often go for a lot of options before selecting the best one. Thus, adoption of technologies in order to introduce the new designs and in order to increase the efficiency of cars on the sale, the industry players are investing on new innovative tools and equipment like the 3-D printing machines. Therefore, the 3-D printing technology, which is a part of the broader term , i.e., additive manufacturing technique, already been utilised in various kind of manufacturing industries across the globe, has huge market potential in the upcoming years within the automobile sector.

According to the higher management of General Motors, the company realise the increased utilisation of technology in every walk of life which makes the processes faster and less rigorous. Thus, they are also utilising the technological advancements to extend and better standardize their operations. The technology of 3-D printing is being adopted by various industries across the U.S. to manufacture rapid prototype parts for manufacturing and design. General Motor is thus adopting this technology to quickly build accessories and tools for the workers at the plant. As per Zane Meike, the lead at the facility of additive manufacturing at General Motors, an approximately 35,000 3-D printing machine, involving housing, at General Motor's Lansing Delta Township plant has saved the company more than USD 300,000 over two years on tools and other accessories. The Lansing Delta Township plant of the company, that manufactures the Buick Enclave and Chevrolet Traverse, originally purchased the 3-D Printing machine to make kitting boxes for parts. However, other usages which were gradually suggested and submitted by plant workers, continue to be adopted in order to improve the safety measures and for savings on the cost on production. In the light of the advantages of 3-D Printing, General Motors is working to standardize 3-D printing and create the best practices within all the plants of the company across the globe.

According to BlueWeave Consulting, the highly competitive automobile industry, in order to satisfy the consumer wants, is working towards all the best class methodologies that help them to integrate new technology with the existing one that include implementation of systems and processes that can further assist human workers. The modern buyer of auto vehicles looks for variety and quality in order to make the purchasing decision and since this product category involves high level of involvement, the buyers often go for a lot of options before selecting the best one. Thus, adoption of technologies in order to introduce the new designs and in order to increase the efficiency of cars on the sale, the industry players are investing on new innovative tools and equipment like the 3-D printing machines. Therefore, the 3-D printing technology, which is a part of the broader term , i.e., additive manufacturing technique, already been utilised in various kind of manufacturing industries across the globe, has huge market potential in the upcoming years within the automobile sector.

According to the higher management of General Motors, the company realise the increased utilisation of technology in every walk of life which makes the processes faster and less rigorous. Thus, they are also utilising the technological advancements to extend and better standardize their operations. The technology of 3-D printing is being adopted by various industries across the U.S. to manufacture rapid prototype parts for manufacturing and design. General Motor is thus adopting this technology to quickly build accessories and tools for the workers at the plant. As per Zane Meike, the lead at the facility of additive manufacturing at General Motors, an approximately 35,000 3-D printing machine, involving housing, at General Motor's Lansing Delta Township plant has saved the company more than USD 300,000 over two years on tools and other accessories. The Lansing Delta Township plant of the company, that manufactures the Buick Enclave and Chevrolet Traverse, originally purchased the 3-D Printing machine to make kitting boxes for parts. However, other usages which were gradually suggested and submitted by plant workers, continue to be adopted in order to improve the safety measures and for savings on the cost on production. In the light of the advantages of 3-D Printing, General Motors is working to standardize 3-D printing and create the best practices within all the plants of the company across the globe.

According to BlueWeave Consulting, the highly competitive automobile industry, in order to satisfy the consumer wants, is working towards all the best class methodologies that help them to integrate new technology with the existing one that include implementation of systems and processes that can further assist human workers. The modern buyer of auto vehicles looks for variety and quality in order to make the purchasing decision and since this product category involves high level of involvement, the buyers often go for a lot of options before selecting the best one. Thus, adoption of technologies in order to introduce the new designs and in order to increase the efficiency of cars on the sale, the industry players are investing on new innovative tools and equipment like the 3-D printing machines. Therefore, the 3-D printing technology, which is a part of the broader term , i.e., additive manufacturing technique, already been utilised in various kind of manufacturing industries across the globe, has huge market potential in the upcoming years within the automobile sector.

According to the higher management of General Motors, the company realise the increased utilisation of technology in every walk of life which makes the processes faster and less rigorous. Thus, they are also utilising the technological advancements to extend and better standardize their operations. The technology of 3-D printing is being adopted by various industries across the U.S. to manufacture rapid prototype parts for manufacturing and design. General Motor is thus adopting this technology to quickly build accessories and tools for the workers at the plant. As per Zane Meike, the lead at the facility of additive manufacturing at General Motors, an approximately 35,000 3-D printing machine, involving housing, at General Motor's Lansing Delta Township plant has saved the company more than USD 300,000 over two years on tools and other accessories. The Lansing Delta Township plant of the company, that manufactures the Buick Enclave and Chevrolet Traverse, originally purchased the 3-D Printing machine to make kitting boxes for parts. However, other usages which were gradually suggested and submitted by plant workers, continue to be adopted in order to improve the safety measures and for savings on the cost on production. In the light of the advantages of 3-D Printing, General Motors is working to standardize 3-D printing and create the best practices within all the plants of the company across the globe.

According to BlueWeave Consulting, the highly competitive automobile industry, in order to satisfy the consumer wants, is working towards all the best class methodologies that help them to integrate new technology with the existing one that include implementation of systems and processes that can further assist human workers. The modern buyer of auto vehicles looks for variety and quality in order to make the purchasing decision and since this product category involves high level of involvement, the buyers often go for a lot of options before selecting the best one. Thus, adoption of technologies in order to introduce the new designs and in order to increase the efficiency of cars on the sale, the industry players are investing on new innovative tools and equipment like the 3-D printing machines. Therefore, the 3-D printing technology, which is a part of the broader term , i.e., additive manufacturing technique, already been utilised in various kind of manufacturing industries across the globe, has huge market potential in the upcoming years within the automobile sector. Related Blog

- Prebiotics consumption expands in food and beverage applications...

- Online education industry – How has COVID-19 impacted the growth dynamics

- Lithium ion batteries continue to gain phenomenal traction in the automotive sector...

- Personal Protective Equipment Industry – 6 Major Application Sectors Driving...